Forging Die Lubricants

Graphite Based Forging Lubricants

- Assured High Performance Specially Developed Micronised Graphite

- Speciality Additives High Lubricity & Releasing Properties

- Assured Consistency In Die Life & Per Tonnage Consumption

- Different Grades Available As Per Applications & Metallurgy Expertise

- Technical Support

Non-Graphite Based Forging Lubricants

- Assured High Performance

- Environment Friendly No Toxic, Hazardous Smoke & Smell Generation

- Speciality Additives High Lubricity, Excellent Layer Formation & Releasing Properties

- Higher Dilution Ratios Assured Consistency In Die Life & Per Tonnage Consumption

- Different Grades Available As Per Applications & Metallurgy Expertise

- Technical Support

Cold Forging Lubricants

- Available Moly Based (Dry & Liquid) Lubricants

- Various Kind Of Polymer Coatings Available

- Tailor Made Solution Available As Per Requirements

- Excellent Scratch Resistance Properties

- Excellent Load Carrying Capacity

Oil Based Lubricants

- Different Grades Available As Per Forging Application Hammer Forging , Critical Extrusions, Hollow Forgings Etc

- Contains Speciality Ep, Releasing & Lubricity

- Additives Improved Material Flow & Tool Life

- Excellent Die Temperature Control

- Excellent Surface Finish Compatable For Both Ferrous & Non-ferrous Extrusions

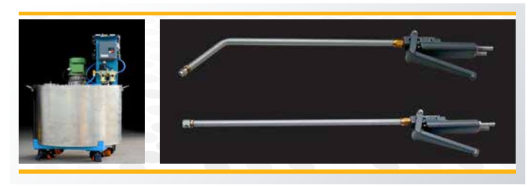

Spray Guns & Spraying Tanks

- Ss/ms Tanks As Per Required Capacity Mounted On Wheeled Trolley.

- Agitator With Impeller, Shaft, Coupling, Gear Box, Motor

- Aodd Pump With Suction Pipe & Fittings Spray Gun, Hose Pipe, All Necessary Hydraulic & Pneumatic Fittings

- Capacity As Per Clients Requirements

- Liquid Can Be Top Up Without Hampering Operation

- Easily Movable

- Economical

- Easy To Operate & Clean

- Long Life

Die Lube Auto Mixing Units

- Stable Dilution Ratio

- Controlled Dilution Ratio

- Can Be Utilised As Centralised Lubrication System

- Increase Productivity

Forging Strength with Every Drop

Yeskolube’s Forging Die Lubricants deliver superior performance, enhanced die life, eco-friendly options, and customized solutions for diverse forging applications.

- Custom Solutions for all forging types and metallurgy needs.

- High Performance with excellent die life and surface finish.

- Eco-Friendly Options with low smoke and operator-safe formulations.

Custom Grades for Every Application

0%

High Lubricity & Release Efficiency

0%

Eco-Friendly Non-Graphite Options

0%

Advanced Additive Technology

0%

Complete Forging Support Systems

0%