Die Casting Lubricants

HPDC Die Coats

- High Performance

- Excellent Layer Formation On Dies At High Temperature

- Wax Free

- Paintable Silicone Based

- Synthetic / Semi-synthetic / Silicone Free As Per Requirement

- Excellent Lubricity & Release Properties

- Excellent Surface Finish

- Lowest Emulsion Costing

- Expertised Technical Support

GDC/PDC Die Coats

- These Die Coats Provide Excellent Release Properties, Ensuring A Smooth And Defect-free Surface Finish On Cast Components.

- The Die Coat Give Die Protection, Reducing Wear And Erosion, And Extending The Lifespan Of The Die.

- Improved Productivity

- These Die Coats Are Engineered To Deliver Consistent Performance And Reliable Results, Ensuring The Casting Quality .

- High In Performance & Low In Cost.

Ladle Coats

- Special refractory paste used in aluminum casting plants for protecting transfer ladles and spoons.

- Offers high resistance to thermal shock and corrosion.

- Excellent non-wetting characteristics, crucial for handling molten aluminum safely.

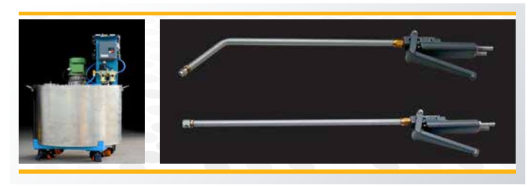

Spray Guns & Spraying Tanks

- Ss/ms Tanks As Per Required Capacity Mounted On Wheeled Trolley.

- Agitator With Impeller, Shaft, Coupling, Gear Box, Motor

- Aodd Pump With Suction Pipe & Fittings Spray Gun, Hose Pipe, All Necessary Hydraulic & Pneumatic Fittings

- Capacity As Per Clients Requirements

- Liquid Can Be Top Up Without Hampering Operation

- Easily Movable

- Economical

- Easy To Operate & Clean

- Long Life

Die Lube Auto Mixing Units

- Stable Dilution Ratio

- Controlled Dilution Ratio

- Can Be Utilised As Centralised Lubrication System

- Increase Productivity

Forging Strength with Every Drop

Yeskolube’s Forging Die Lubricants deliver superior performance, enhanced die life, eco-friendly options, and customized solutions for diverse forging applications.

- Custom Solutions for all forging types and metallurgy needs.

- High Performance with excellent die life and surface finish.

- Eco-Friendly Options with low smoke and operator-safe formulations.

Custom Grades for Every Application

0%

High Lubricity & Release Efficiency

0%

Eco-Friendly Non-Graphite Options

0%

Advanced Additive Technology

0%

Complete Forging Support Systems

0%